BLANKET are light-weight, weather-resistant and durable.

No wire, banding straps, or special tools are required. Everything needed for installation is part of the jacket. We can do modifications and repairs in the field. No other fire protection system allows the ease of removal and reinstallation integrity ensured by our jackets.

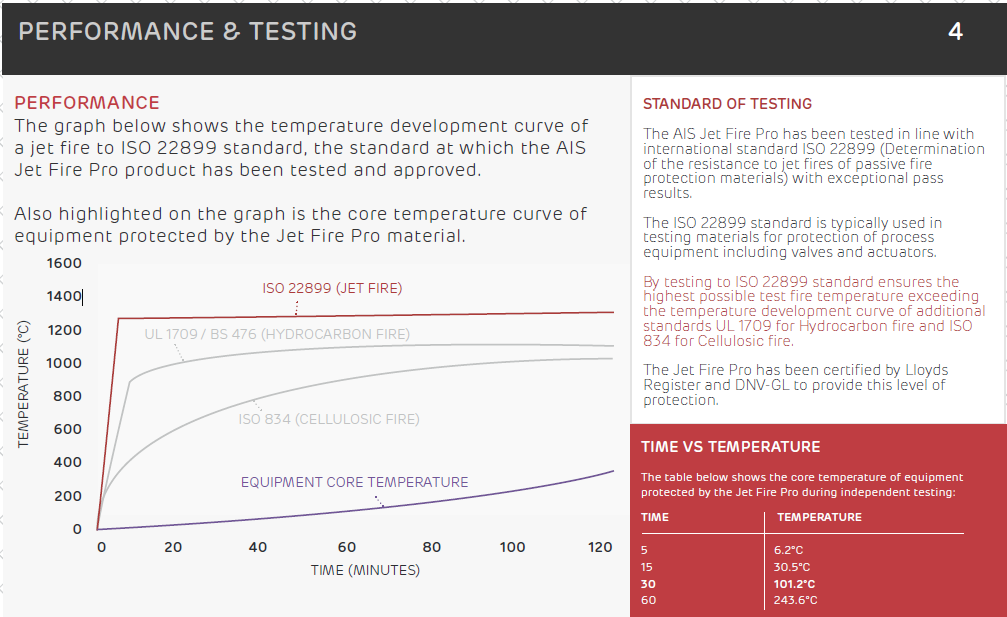

They have been extensively tested over a range of different fire tests from cellulosic and hydrocarbon fire test up to full-scale jet fire tests. Having qualified to many “UL1709” fire tests, the jacket design was the first to pass the rigorous full-scale jet fire. More recently the jacket has been tested to the latest OTI 95 634 standard. Our jackets meet a wide range of fire durations and limiting temperatures. Typically these are in the range of 15 to 120 minutes, but longer duration fires can be designed for if required.The systems designed & tested are capable of protecting items to a range of critical temperatures. The blast overpressure testing was carried out and resulted in overpressures of 0.8 bar, 1.25 bar and 1.46 bar and demonstrated the jacket’s ability to withstand repeated exposure to blast and drag forces, without compromising its fire performing construction.

01 -INTERGRAL INSPECTION HATCH FOR IMMEDIATE ACCESS

02 – BUCKLES & STRAPS

03 – VELCRO ON 3 SIDES OF HATCH

04 – 4th SIDE SECURED TO REMAINDER OF JACKET (NO LOOSE PIECES)